|

PRODUCTS |

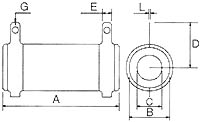

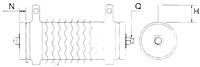

| NON-FLAMMABLE FIXED WIREWOUND POWER RESISTORS (NPW) |

|

DR Series |

|

|

|

¡@ |

|

|

|

|

|

|

|

Rated |

Dimension (mm) | ||||||||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | |

| 10W | 45 | 12 | 6 | 15 | 4 | 54 | 2 | 9 | 3 | 62 | 28 | 1.0 | 6 | 10 | M3X68 | ||

| 20W | 60 | 17 | 8 | 22 | 5 | 78 | 2 | 12 | 4 | 90 | 36 | 1.0 | ¡@ | 6 | 16 | M3X68 | M4X88 |

| 30W | 80 | 17 | 8 | 22 | 5 | 100 | 2 | 12 | 4 | 112 | 36 | 1.0 | 6 | 16 | M4X88 | M4X108 | |

| 40W | 110 | 17 | 8 | 22 | 5 | 128 | 2 | 12 | 4 | 140 | 36 | 1.0 | ¡@ | 6 | 16 | M4X118 | M5X135 |

| 50W | 110 | 25 | 16 | 30 | 8 | 150 | 5 | 18 | 6 | 166 | 58 | 1.2 | 6 | 27 | M5X135 | M5X135 | |

| 60W | 90 | 28 | 18 | 32 | 8 | 130 | 5 | 19 | 6 | 146 | 60 | 1.2 | 6 | ¡@ | 27 | M4X115 | M4X115 |

| 80W | 110 | 28 | 18 | 32 | 8 | 150 | 5 | 19 | 6 | 166 | 60 | 1.2 | 6 | ¡@ | 27 | M5X135 | M5X135 |

| 100W | 140 | 28 | 18 | 32 | 8 | 180 | 5 | 19 | 6 | 196 | 60 | 1.2 | 6 | ¡@ | 27 | M5X165 | M5X165 |

| 120W | 160 | 28 | 18 | 32 | 8 | 200 | 5 | 19 | 6 | 216 | 60 | 1.2 | 6 | ¡@ | 27 | M5X185 | M5X185 |

| 150W | 195 | 28 | 18 | 32 | 8 | 235 | 5 | 19 | 6 | 251 | 60 | 1.2 | 6 | ¡@ | 27 | M5X230 | M5X230 |

| 160W | 185 | 35 | 24 | 36 | 10 | 225 | 5 | 19 | 8 | 245 | 76 | 1.6 | 6 | ¡@ | 34 | M5X210 | M5X210 |

| 200W | 210 | 35 | 24 | 36 | 10 | 250 | 5 | 19 | 8 | 274 | 76 | 1.6 | 6 | ¡@ | 34 | M5X245 | M5X245 |

| 250W | 210 | 40 | 25 | 38 | 12 | 250 | 5 | 20 | 8 | 274 | 78 | 1.6 | 6 | ¡@ | 34 | M5X245 | M5X245 |

| 300W | 260 | 40 | 25 | 38 | 12 | 300 | 5 | 20 | 8 | 320 | 78 | 1.6 | 6 | ¡@ | 34 | M5X295 | M5X295 |

| 400W | 330 | 40 | 25 | 38 | 12 | 370 | 5 | 20 | 8 | 395 | 78 | 1.6 | 6 | ¡@ | 34 | M5X365 | M5X365 |

| 500W | 330 | 50 | 35 | 50 | 12 | 380 | 6 | 25 | 9 | 400 | 100 | 1.6 | 6 | ¡@ | 40 | M5X365 | M5X365 |

| 600W | 400 | 50 | 35 | 50 | 12 | 450 | 6 | 25 | 9 | 470 | 100 | 1.6 | 8 | ¡@ | 40 | M5X435 | M5X435 |

| 700W | 460 | 50 | 35 | 50 | 12 | 510 | 6 | 25 | 9 | 530 | 100 | 1.6 | 8 | ¡@ | 40 | M5X495 | M5X495 |

| 800W | 460 | 60 | 40 | 55 | 15 | 515 | 6 | 30 | 10 | 535 | 110 | 1.6 | 108 | ¡@ | 50 | M5X495 | M5X495 |

| 1000W | 540 | 60 | 40 | 55 | 15 | 595 | 6 | 30 | 10 | 615 | 110 | 1.6 | 10 | ¡@ | 50 | M6X580 | M5X580 |

| 1300W | 650 | 65 | 42 | 62 | 15 | 702 | 6 | 30 | 10 | 722 | 115 | 1.6 | 10 | ¡@ | 50 | M6X690 | M5X690 |

|

DR Resistor Series: |

|||||||||||||||||

|

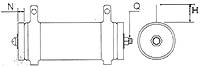

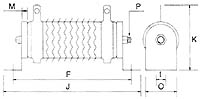

DQ Series |

|

|

|

|

|

|

Rated |

Dimensions (mm) | |||||||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | M | O | P | Q | |

| 75W | 110 | 25 | 16 | 30 | 8 | 150 | 5 | 18 | 6 | 166 | 58 | 1.2 | 6 | 27 | M5X135 | M5X135 |

| 90W | 90 | 28 | 18 | 32 | 8 | 130 | 5 | 19 | 6 | 146 | 60 | 1.2 | 6 | 27 | M5X115 | M5X115 |

| 120W | 110 | 28 | 18 | 32 | 8 | 150 | 5 | 19 | 6 | 166 | 60 | 1.2 | 6 | 27 | M5X135 | M5X135 |

| 150W | 140 | 28 | 18 | 32 | 8 | 180 | 5 | 19 | 6 | 196 | 60 | 1.2 | 6 | 27 | M5X165 | M5X165 |

| 180W | 160 | 28 | 18 | 32 | 8 | 200 | 5 | 19 | 6 | 216 | 60 | 1.2 | 6 | 27 | M5X185 | M5X185 |

| 225W | 195 | 28 | 18 | 32 | 8 | 235 | 5 | 19 | 6 | 251 | 60 | 1.2 | 6 | 27 | M5X230 | M5X230 |

| 240W | 185 | 35 | 24 | 36 | 10 | 225 | 5 | 19 | 8 | 245 | 76 | 1.6 | 6 | 34 | M5X210 | M5X210 |

| 300W | 210 | 35 | 24 | 36 | 10 | 250 | 5 | 19 | 8 | 274 | 76 | 1.6 | 6 | 34 | M5X245 | M5X245 |

| 375W | 210 | 40 | 25 | 38 | 12 | 250 | 5 | 20 | 8 | 274 | 78 | 1.6 | 6 | 34 | M5X245 | M5X245 |

| 450W | 260 | 40 | 25 | 38 | 12 | 300 | 5 | 20 | 8 | 320 | 78 | 1.6 | 6 | 34 | M5X295 | M5X295 |

| 600W | 330 | 40 | 25 | 38 | 12 | 370 | 5 | 20 | 8 | 395 | 78 | 1.6 | 6 | 34 | M5X365 | M5X365 |

| 750W | 330 | 50 | 35 | 50 | 12 | 380 | 6 | 25 | 9 | 400 | 100 | 1.6 | 8 | 40 | M5X365 | M5X365 |

| 900W | 400 | 50 | 35 | 50 | 12 | 450 | 6 | 25 | 9 | 470 | 100 | 1.6 | 8 | 40 | M5X435 | M5X435 |

| 1000W | 460 | 50 | 35 | 50 | 12 | 510 | 6 | 25 | 9 | 530 | 100 | 1.6 | 8 | 40 | M5X495 | M5X495 |

| 1200W | 460 | 60 | 40 | 55 | 15 | 515 | 6 | 30 | 10 | 535 | 110 | 1.6 | 10 | 50 | M5X495 | M5X495 |

| 1500W | 540 | 60 | 40 | 55 | 15 | 595 | 6 | 30 | 10 | 615 | 110 | 1.6 | 10 | 50 | M6X580 | M5X580 |

| 2000W | 650 | 65 | 42 | 62 | 15 | 702 | 6 | 30 | 10 | 722 | 115 | 1.6 | 10 | 50 | M6X690 | M5X690 |

|

DQ Resistor Series: |

||||||||||||||||

| ¡@ |

|

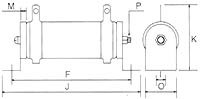

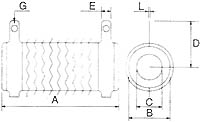

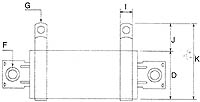

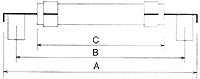

ZR Series |

|

|

|

|

|

|

Rated |

Dimensions (mm) | |||||||||||

|

ZZR TYPE |

A | B | C | D | E | F | G | H | I | J | K | ZQR TYPE |

| 40W | 83 | 70 | 50 | 28 | 11 | 5.2 | 4.1 | 13 | 6.5 | 12 | 42 | 60W |

| 55W | 123 | 110 | 90 | 28 | 11 | 5.2 | 4.1 | 13 | 6.5 | 12 | 42 | 82W |

| 70W | 153 | 140 | 120 | 28 | 11 | 5.2 | 4.1 | 13 | 6.5 | 12 | 42 | 105W |

| 95W | 183 | 170 | 150 | 28 | 11 | 5.2 | 4.1 | 13 | 6.5 | 12 | 42 | 140W |

| 100W | 193 | 180 | 160 | 28 | 11 | 5.2 | 4.1 | 13 | 6.5 | 12 | 42 | 150W |

| 120W | 218 | 205 | 185 | 28 | 11 | 5.2 | 4.1 | 13 | 6.5 | 12 | 42 | 180W |

| 150W | 218 | 205 | 185 | 35 | 11 | 5.2 | 5.2 | 13 | 9 | 13 | 46 | 225W |

| 200W | 243 | 230 | 210 | 35 | 11 | 5.2 | 5.2 | 13 | 9 | 13 | 46 | 300W |

| 250W | 287 | 274 | 254 | 35 | 11 | 5.2 | 5.2 | 13 | 9 | 13 | 48 | 375W |

| 300W | 333 | 320 | 300 | 35 | 11 | 5.2 | 5.2 | 13 | 9 | 13 | 48 | 450W |

|

ZR Resistor Series: |

||||||||||||

|

|

|

|

|

|

|

Copyright (c) 2023~2033

All-Have Corporation. All rights reserved. |